|

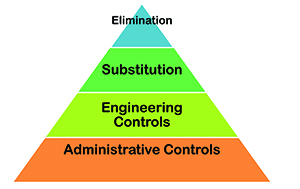

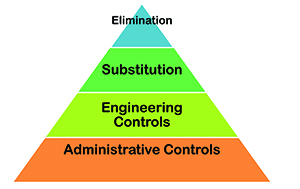

The strategies are listed in order of effectiveness.

Eliminate

- Avoid installation of horizontal surfaces where dust can accumulate.

- Eliminate "hidden" areas where dust can accumulate.

- Eliminate the use of compressed air for cleaning surfaces.

- Eliminate point sources for fugitive dusts (i.e., leaks, patches, etc.)

Substitution

- Install smooth ceiling and wall surfaces (instead of rough finish) to minimize dust accumulation and allow effective cleaning.

- Install enclosed conveyance systems to replace "open" systems.

Engineering Controls

- Install dust collection systems at transfer points, truck receiving/loadout areas, inside bucket elevators, conveyance, etc.

- Locate dust collectors (baghouses) o the exterior of structures/buildings. If located inside a structure, ensure dust collectors/baghouses are adequately vented and have adequate fire separation, and or explosion suppression. Always direct deflagration venting away from areas that are occupied by employees.

- Ensure proper electrical classifications are used when installing/retrofitting equipment (i.e. Class II).

- Install hazard monitoring (motion detection, belt alignment, bearing temperature monitoring) on bucket elevator legs and conveyance.

- Install deflagration suppression systems on bucket elevator legs.

- Install deflagration suppression systems on interior dust collection (i.e.) baghouses).

- Install oil-addition system (food grade) to reduce dust levels.

- Pressurize interior areas to reduce fugitive dust.

- Prevent tramp metal from entering the product stream by using magnets and properly sized granting at receiving areas.

- Install magnets to remove metal from the process flow.

Administrative Controls

- Develop and implement a combustible dust inspection program to identify housekeeping opportunities.

- Develop and implement a written housekeeping program that defines the responsibility, frequency, and acceptable methods for cleaning.

- Develop, implement, and enforce a hot work permit program.

- Develop, implement, and enforce the "No Smoking" policy.

- Educate employees, contractors, visitors, and drivers on the hazards of combustible dust including common ignition sources such as smoking.

- Implement cleaning techniques that minimize placing dust in suspension.

- If using compressed air for cleaning, implement a permit system that requires the elimination of ignition sources during cleaning activities.

- Develop and implement a documented preventive maintenance program that defines the types of equipment inspected (bucket elevator leg, drying equipment, conveyance, dust collection, etc.) frequency of inspection, inspection elements, etc.

- Develop and implement a routine inspection program to identify point sources of fugitive dust to include bucket elevators, distributors, conveyance enclosures, dust collection equipment, spouting, etc.

- Develop and implement a program for inspecting and cleaning magnets.

Source: Joe Mlynek is president of Progressive Safety Services LLC, Gates Mills, OH; joe.mlynek@progressivesafety.us; and content creation expert for Safety Made Simple, Inc., Olathe, KS; joe@safetymadesimple.com

|

|